Selecting the right floor mats for your vehicle, workspace, or recreational equipment is a crucial decision that impacts both safety and longevity. Whether you're looking to protect your car's interior, enhance workplace safety, or maintain the pristine condition of specialized vehicles like golf carts, understanding the key factors in floor mat selection can save you money and prevent potential hazards. The right floor mats serve as the first line of defense against dirt, moisture, wear, and tear while providing essential traction and comfort for users.

Modern floor protection solutions have evolved significantly from simple rubber sheets to engineered products that combine durability, aesthetics, and functionality. The market offers an extensive range of materials, designs, and specialized features tailored to specific applications. Understanding these options helps ensure you invest in protection that delivers long-term value while meeting your specific requirements for safety, maintenance, and performance.

Essential Material Considerations for Optimal Protection

Rubber Composition and Durability Factors

Rubber remains one of the most popular materials for protective floor mats due to its excellent water resistance and flexibility. High-quality rubber mats feature dense molecular structures that resist cracking, splitting, and degradation from temperature fluctuations. Natural rubber offers superior grip and comfort but may require more maintenance in extreme conditions. Synthetic rubber compounds, including nitrile and neoprene, provide enhanced chemical resistance and longer service life in demanding environments.

The thickness of rubber floor mats directly correlates with their protective capabilities and longevity. Thicker mats generally offer better cushioning and insulation properties while providing superior barrier protection against moisture and debris. However, excessive thickness can create tripping hazards or interfere with mechanical components in vehicles. The optimal thickness typically ranges from 3mm for light-duty applications to 12mm for heavy-duty industrial use.

Plastic and Polymer Alternatives

Thermoplastic materials offer distinct advantages in certain applications, particularly where chemical resistance and easy cleaning are priorities. High-density polyethylene and polypropylene mats resist most common chemicals while maintaining structural integrity under heavy loads. These materials typically feature lower profiles than rubber alternatives, making them ideal for applications where clearance is limited. The non-porous surface of quality plastic mats prevents bacteria and odor accumulation, making them excellent choices for food service and healthcare environments.

Advanced polymer formulations incorporate UV stabilizers and anti-static properties to extend service life and prevent electronic interference. Some specialized plastic floor mats include embedded fiberglass reinforcement for additional strength without significantly increasing weight. These engineered solutions often provide the best balance of performance and cost-effectiveness for commercial applications requiring frequent cleaning and sanitization.

Size and Fit Specifications

Precise Measurement Techniques

Accurate measurement forms the foundation of effective floor mat selection, particularly for custom or semi-custom applications. Begin by measuring the length and width of the protected area, accounting for any irregular shapes or obstacles that might affect mat placement. Consider the relationship between mat edges and surrounding surfaces, ensuring adequate coverage without creating gaps where debris can accumulate. Professional installation often requires measurements at multiple points to accommodate variations in floor levelness or manufacturing tolerances.

Digital measuring tools and smartphone applications can improve accuracy while providing documentation for future reference. When measuring curved or irregular spaces, create paper templates to verify fit before ordering custom mats. Remember that some materials may expand or contract with temperature changes, requiring slight adjustments in sizing calculations. Factor in any mounting hardware or attachment mechanisms that might affect the final installed dimensions.

Coverage Area Optimization

Strategic coverage planning maximizes protection while minimizing material costs and maintenance requirements. Focus protection on high-traffic areas and zones prone to moisture or debris accumulation. Consider traffic patterns and user behavior when determining coverage boundaries, ensuring mats extend sufficiently beyond primary use areas to capture spillover effects. Overlapping coverage areas may require careful attention to edge transitions to prevent tripping hazards or water collection.

Modular floor mats offer flexibility in coverage optimization, allowing for partial replacement and reconfiguration as needs change. Interlocking systems enable seamless expansion while maintaining consistent protection levels across larger areas. This approach proves particularly valuable in commercial settings where usage patterns may evolve or where phased installation helps manage budget constraints.

Safety and Traction Features

Surface Texture and Grip Enhancement

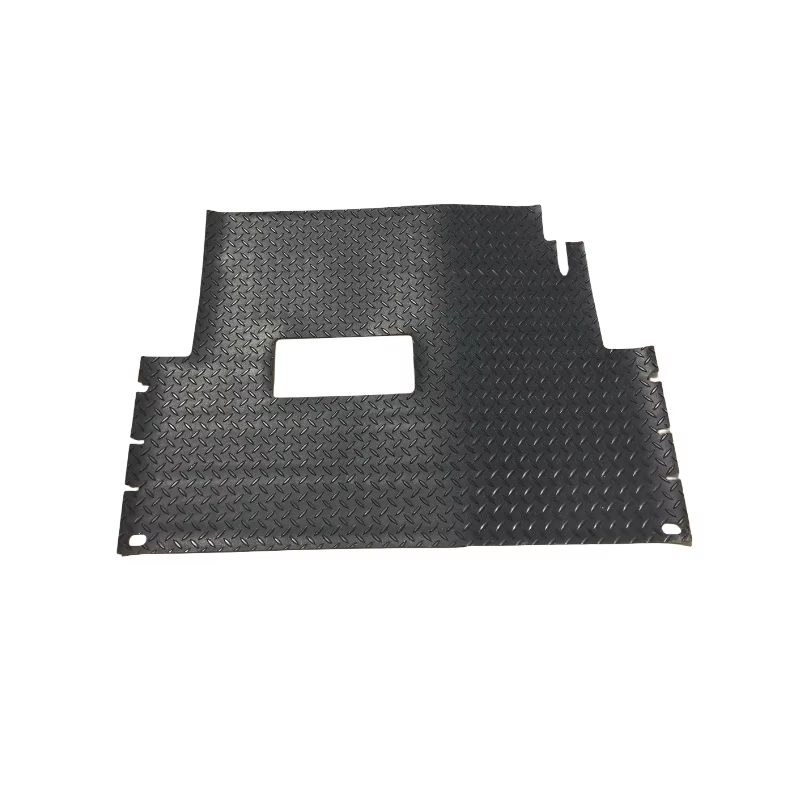

Surface texture plays a critical role in preventing slips and falls while maintaining easy cleaning capabilities. Diamond plate patterns provide excellent multi-directional traction while allowing efficient debris removal through raised channels. Ribbed surfaces offer good grip in specific directions but may trap certain types of contaminants. Smooth surfaces with subtle texture provide adequate traction for most applications while facilitating thorough cleaning and sanitization procedures.

The relationship between surface texture and footwear type affects overall safety performance. Deep textures work well with rubber-soled shoes but may be uncomfortable for barefoot use. Conversely, subtle textures accommodate various footwear types while maintaining professional appearance standards. Consider the primary user demographic and typical footwear when evaluating texture options, as this significantly impacts both safety and user satisfaction.

Edge Design and Transition Management

Proper edge design prevents tripping hazards while maintaining effective barrier protection. Beveled edges create smooth transitions between mat surfaces and surrounding floors, reducing catch points for wheeled equipment and foot traffic. The bevel angle should provide adequate transition slope without compromising the mat's ability to contain spills or debris. Reinforced edges resist curling and damage from repeated impact, extending overall mat life significantly.

Raised edge designs contain liquids and debris more effectively but require careful consideration of clearance requirements. Full perimeter containment works well for stationary applications but may interfere with equipment access or create maintenance challenges. Selective edge raising on specific sides can provide targeted containment while maintaining accessibility where needed.

Maintenance and Cleaning Requirements

Cleaning Protocol Compatibility

Different mat materials require specific cleaning approaches to maintain appearance and performance over time. Rubber mats generally tolerate aggressive cleaning agents and high-pressure washing but may degrade when exposed to petroleum-based solvents. Plastic mats resist most chemical cleaners but can become brittle if exposed to excessive heat during cleaning processes. Understanding material compatibility with existing cleaning protocols prevents premature deterioration and ensures consistent protection performance.

Textured surfaces may trap debris more readily than smooth alternatives, requiring modified cleaning techniques or more frequent attention. Deep textures benefit from brush scrubbing or specialized cleaning equipment to remove embedded contaminants. Consider the availability of appropriate cleaning tools and staff training requirements when evaluating texture options, as inadequate cleaning can negate the protective benefits of quality floor mats.

Long-term Durability Factors

Environmental conditions significantly impact floor mat longevity and performance characteristics. UV exposure gradually breaks down polymer chains in both rubber and plastic materials, leading to cracking, fading, and loss of flexibility. Temperature cycling accelerates this degradation process, particularly in outdoor applications or unheated spaces. Quality mats incorporate UV stabilizers and temperature-resistant formulations to minimize these effects, but proper selection still requires matching material properties to expected conditions.

Chemical exposure from cleaning agents, spilled materials, or environmental contamination can cause swelling, hardening, or surface deterioration in susceptible materials. Resistance testing data from manufacturers helps predict performance in specific chemical environments, but real-world conditions often involve multiple contaminants and varying concentrations. Regular inspection and rotation of floor mats can help identify developing issues before they compromise protection effectiveness.

Cost-Effectiveness and Value Analysis

Initial Investment Considerations

Quality floor mats represent a significant upfront investment that pays dividends through reduced maintenance costs and extended surface life. Premium materials and construction typically command higher initial prices but deliver superior performance and longevity compared to economy alternatives. The cost differential often represents less than the expense of a single floor refinishing or replacement project, making quality mats an excellent value proposition for most applications.

Bulk purchasing opportunities can reduce per-unit costs significantly, particularly for large installations or multiple locations. However, avoid over-purchasing materials that may degrade in storage or become obsolete due to changing requirements. Consider phased installation approaches that capture volume discounts while allowing for performance evaluation and requirement refinement over time.

Lifecycle Cost Evaluation

Total cost of ownership includes initial purchase price, installation expenses, ongoing maintenance costs, and replacement frequency. High-quality floor mats often provide service lives three to five times longer than economy alternatives while requiring less frequent deep cleaning or repair. Factor in labor costs for installation and maintenance when comparing options, as easy-to-clean materials can provide substantial savings over time despite higher initial costs.

Warranty coverage reflects manufacturer confidence in product durability and can provide valuable protection against premature failure. Comprehensive warranties typically cover material defects, excessive wear, and performance degradation under normal use conditions. Document usage conditions and maintenance practices to ensure warranty compliance and maximize protection against unexpected replacement costs.

FAQ

What thickness should I choose for heavy-duty applications?

Heavy-duty applications typically require floor mats between 8-12mm thick to provide adequate cushioning and protection. Thicker mats offer better insulation and impact resistance but may create clearance issues with doors or equipment. Consider the specific load requirements and traffic patterns when selecting thickness, as excessive thickness in low-clearance areas can create safety hazards or operational difficulties.

How do I determine the right material for outdoor use?

Outdoor floor mats must resist UV degradation, temperature cycling, and moisture exposure while maintaining traction in various weather conditions. Synthetic rubber compounds with UV stabilizers offer the best balance of durability and performance for most outdoor applications. Avoid natural rubber materials in areas with extreme temperature variations, as they may become brittle in cold conditions or soft in excessive heat.

Can I cut standard mats to fit irregular spaces?

Most rubber and plastic floor mats can be cut to accommodate irregular spaces using appropriate tools and techniques. Use sharp utility knives or specialized cutting tools to ensure clean edges that resist tearing or fraying. Seal cut edges with appropriate treatments to prevent moisture infiltration and maintain material integrity. However, extensive modifications may void manufacturer warranties and compromise overall performance.

How often should floor mats be replaced?

Replacement frequency depends on usage intensity, environmental conditions, and material quality. High-traffic commercial applications may require replacement every 2-3 years, while residential or light commercial use may extend service life to 5-7 years. Monitor mat condition regularly for signs of excessive wear, cracking, or loss of traction properties. Replace mats promptly when they no longer provide adequate protection or create safety hazards due to deterioration.