Floor mats serve as an essential protective barrier between your vehicle's interior and the daily wear and tear that comes with regular use. Whether you're dealing with muddy shoes, spilled beverages, or general dirt accumulation, quality floor mats provide a crucial first line of defense for your car's carpeting and flooring surfaces. Beyond basic protection, these accessories can significantly extend the lifespan of your vehicle's interior while maintaining its resale value and aesthetic appeal.

The investment in proper floor protection pays dividends over time, as replacing damaged carpeting can cost hundreds or even thousands of dollars depending on your vehicle type. Modern automotive floor mats have evolved from simple rubber sheets to sophisticated protective systems designed for specific vehicle models and usage patterns. Understanding how these protective accessories work and selecting the right type for your needs can make the difference between a well-preserved interior and costly repairs down the road.

Understanding Floor Mat Protection Mechanisms

Physical Barrier Protection

Floor mats create a physical barrier that prevents direct contact between external contaminants and your vehicle's original carpeting. This barrier function operates on multiple levels, from blocking liquid spills to trapping debris before it can embed into carpet fibers. The effectiveness of this protection depends largely on the mat's material composition, thickness, and coverage area. High-quality mats feature raised edges and textured surfaces that channel liquids away from vulnerable areas while providing secure footing for passengers.

The strategic placement of floor mats covers high-traffic areas where wear patterns typically develop first. Driver-side mats, in particular, must withstand constant heel pressure and pivoting motions that can quickly degrade unprotected carpeting. Passenger areas benefit from protection against dropped items, tracked-in moisture, and the occasional spill. By intercepting these daily challenges, floor mats prevent the gradual deterioration that transforms pristine interiors into worn, stained surfaces over months and years of use.

Moisture Management Systems

Effective moisture management represents one of the most critical functions of modern floor mats. Water, snow, mud, and other liquids pose serious threats to vehicle interiors, potentially causing mold growth, unpleasant odors, and permanent staining. Advanced mat designs incorporate channels, wells, and absorbent materials specifically engineered to capture and contain moisture before it reaches the underlying surfaces. Some premium options feature waterproof backing materials that create an impermeable seal against liquid penetration.

The ability to manage moisture extends beyond simple containment to include proper drainage and drying capabilities. Well-designed mats allow trapped moisture to evaporate gradually without creating humidity buildup that could promote bacterial or fungal growth. This controlled moisture management system protects not only the visible carpeting but also the underlying padding and subfloor materials that are expensive and difficult to replace if damaged by prolonged water exposure.

Material Technologies and Design Features

Rubber and Synthetic Compounds

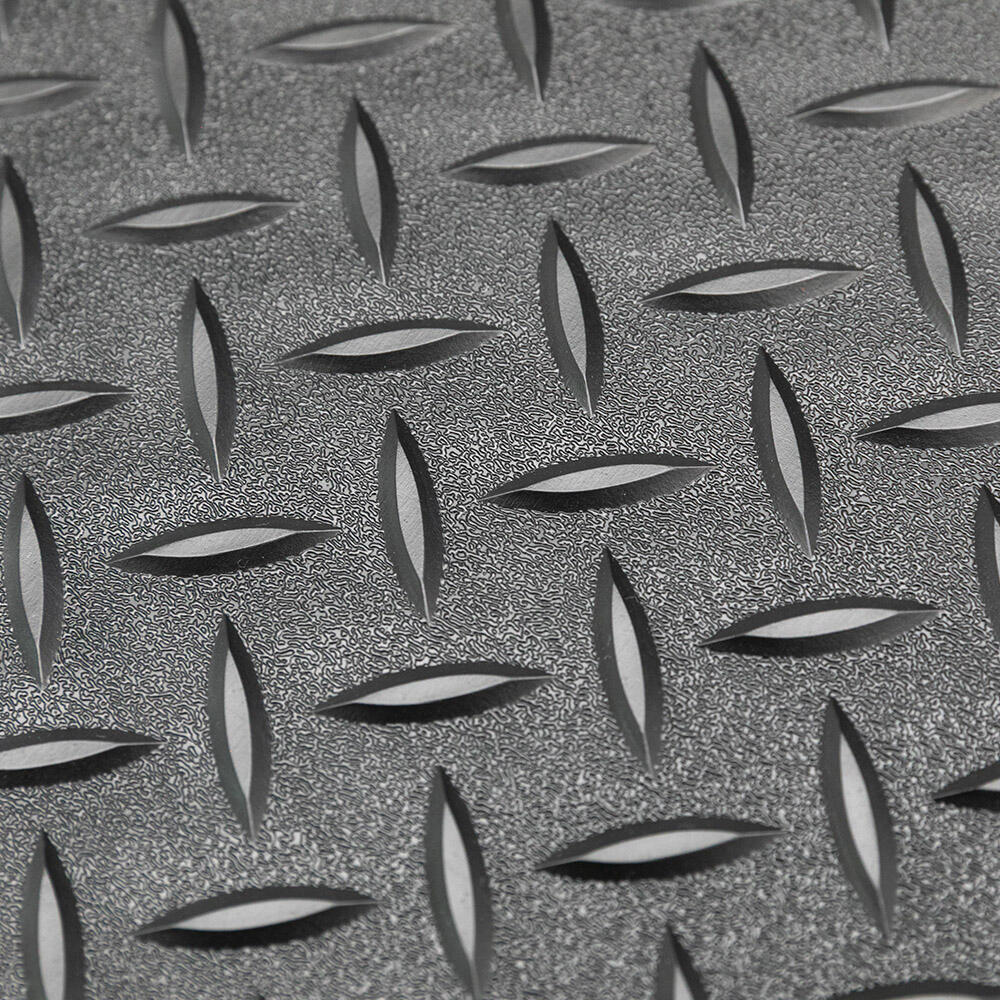

Rubber floor mats represent the most popular choice for heavy-duty protection due to their exceptional durability and easy maintenance characteristics. Modern rubber compounds resist cracking, fading, and deterioration even under extreme temperature variations and constant use. These materials provide excellent grip properties that prevent slipping while offering resistance to most automotive fluids, cleaning chemicals, and environmental contaminants. The flexibility of rubber allows for precise molding to match specific vehicle floor contours, ensuring maximum coverage and protection.

Synthetic polymer blends have emerged as premium alternatives that combine the best characteristics of traditional rubber with enhanced performance features. These advanced materials often incorporate UV stabilizers to prevent color degradation, antimicrobial additives to resist odor-causing bacteria, and specialized texturing for improved traction and debris capture. The manufacturing precision possible with synthetic compounds enables the creation of intricate drainage patterns and custom-fit designs that maximize protection while maintaining aesthetic appeal.

Carpet and Textile Options

Carpet-style floor mats offer a balance between protection and interior aesthetics, particularly appealing to drivers who prioritize visual integration with existing décor. These mats typically feature dense, low-pile fibers that resist matting and staining while providing adequate protection for moderate-use scenarios. The backing materials in quality carpet mats include moisture barriers and anti-slip compounds that secure the mat in position while protecting against liquid penetration to the vehicle's original flooring.

Textile innovations have introduced performance fibers that combine the appearance of traditional carpet with enhanced protective capabilities. Solution-dyed nylon and polypropylene fibers resist fading and staining while maintaining their appearance through repeated cleaning cycles. Some premium carpet mats incorporate multi-layer construction with absorbent cores sandwiched between protective surface layers, creating systems that can handle significant moisture loads without allowing breakthrough to the vehicle's carpeting.

Installation and Fit Considerations

Custom Fit Versus Universal Options

Custom-fit floor mats designed specifically for individual vehicle models provide superior protection through precise coverage of vulnerable areas and secure positioning systems. These mats typically feature exact contours that match floor pan shapes, pedal clearances, and seat mounting locations. The precise fit eliminates gaps where debris could accumulate while ensuring that mat edges don't interfere with pedal operation or seat adjustment mechanisms. Many custom options include integrated retention systems that prevent sliding or bunching during normal use.

Universal floor mats offer cost-effective protection for budget-conscious consumers or those with multiple vehicles requiring similar protection levels. While these mats may not provide the exact fit of custom options, quality universal designs incorporate adjustable features and generous sizing that accommodates most vehicle types. The trade-off between cost and perfect fit makes universal mats attractive for commercial fleets, rental vehicles, or situations where basic protection is more important than aesthetic integration with the vehicle's interior.

Retention and Security Systems

Proper mat retention prevents dangerous shifting that could interfere with pedal operation or create tripping hazards for passengers. Modern retention systems range from simple hook-and-loop fasteners to sophisticated mechanical anchoring systems that integrate with factory floor attachment points. The most effective systems secure mats at multiple points while allowing easy removal for cleaning or replacement. Driver-side mats require particularly robust retention given the constant forces applied during normal driving operations.

Advanced retention technologies include weighted backing systems that use mat weight to maintain position, magnetic attachment systems for metal floor pans, and custom-molded clips that engage specific vehicle mounting points. The selection of appropriate retention methods depends on usage patterns, vehicle design, and user preferences for removal frequency. Professional installation may be recommended for complex retention systems to ensure proper function and avoid potential safety issues.

Maintenance and Longevity Strategies

Cleaning Protocols and Procedures

Regular maintenance of floor mats directly impacts both their protective effectiveness and longevity. Rubber and synthetic mats generally require simple cleaning procedures involving removal, rinsing, and air drying, while carpet-style options may need more intensive care including vacuuming, spot treatment, and occasional deep cleaning. The frequency of cleaning depends on usage patterns, environmental conditions, and the type of contaminants encountered. High-traffic vehicles or those used in harsh conditions may require weekly cleaning to maintain optimal protection levels.

Proper cleaning techniques preserve mat integrity while ensuring thorough contaminant removal. Harsh chemicals or abrasive cleaning methods can damage protective coatings, alter surface textures, or cause premature deterioration of mat materials. Manufacturer guidelines typically specify recommended cleaning products and procedures that maintain warranty coverage while maximizing mat performance. Some advanced mats feature antimicrobial treatments that require specific care procedures to maintain their effectiveness over time.

Replacement Timing and Indicators

Recognition of replacement indicators helps ensure continuous protection before mat failure compromises vehicle interior surfaces. Visible wear patterns, such as thinning areas, cracking, or permanent deformation, signal diminished protective capability. Retention system failures, persistent odors, or inability to achieve cleanliness through normal maintenance procedures also indicate replacement needs. The timing of replacement depends on mat quality, usage intensity, and maintenance consistency, with premium mats typically providing several years of service under normal conditions.

Proactive replacement scheduling prevents the period of vulnerability that occurs when worn mats fail to provide adequate protection. Fleet operators and high-mileage drivers often establish replacement schedules based on mileage intervals or calendar periods rather than waiting for obvious failure signs. This approach ensures continuous protection while allowing budget planning for replacement costs. Some manufacturers offer replacement programs or warranties that guarantee protection levels for specified periods or usage levels.

FAQ

How often should I replace my vehicle floor mats

Floor mat replacement frequency depends on usage patterns, environmental conditions, and mat quality. High-quality rubber mats typically last 3-5 years under normal use, while carpet-style mats may need replacement every 2-3 years. Commercial vehicles or those used in harsh conditions may require annual replacement. Key indicators for replacement include visible wear, cracking, persistent odors, or loss of retention system effectiveness.

Can floor mats prevent all types of interior damage

While floor mats provide excellent protection against most common threats like spills, dirt, and wear, they cannot prevent all types of interior damage. Mats primarily protect floor surfaces and lower portions of seats and door panels within their coverage area. They cannot protect against UV damage, cigarette burns, or damage from sharp objects that penetrate the mat material. Comprehensive interior protection requires multiple strategies including window tinting, seat covers, and careful use practices.

Do custom-fit mats provide significantly better protection than universal options

Custom-fit mats generally provide superior protection through precise coverage and secure retention systems designed for specific vehicle models. They eliminate gaps where debris could accumulate and ensure proper pedal clearance for safety. However, high-quality universal mats can provide adequate protection for many applications at lower cost. The choice depends on protection requirements, budget considerations, and aesthetic preferences.

What maintenance is required to keep floor mats effective

Regular maintenance involves removing mats for cleaning, typically weekly for high-use vehicles or monthly for average use. Rubber mats require simple rinsing and air drying, while carpet mats need vacuuming and occasional deep cleaning. Inspect retention systems periodically and replace worn fasteners to maintain secure positioning. Proper maintenance extends mat life and ensures continued protection effectiveness throughout their service period.